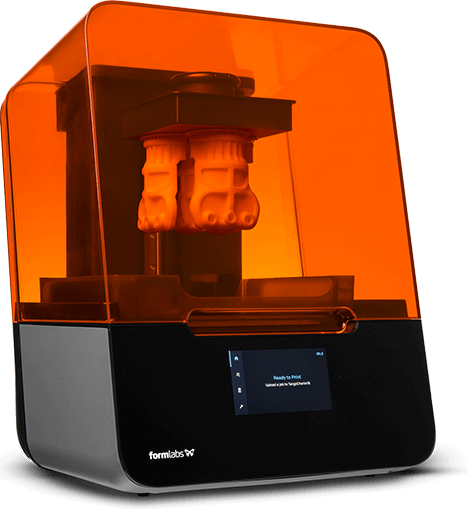

Formlabs Form 3

Formlabs FORM 3

Flawless Prints, Every Time

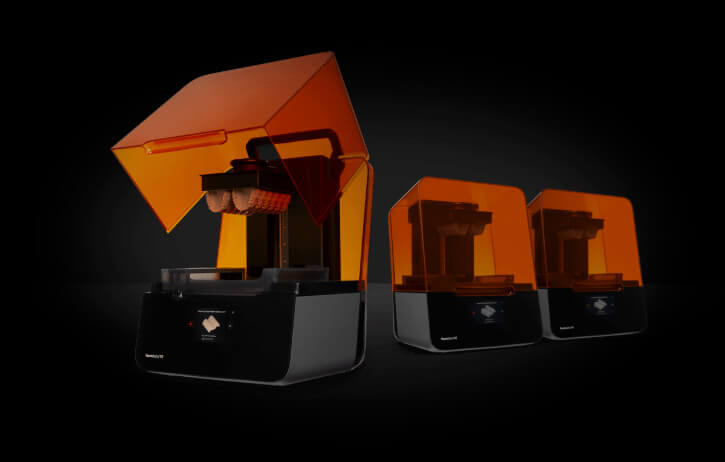

With the Form 3 you get a scalable and affordable prototyping and production platform. Ready to grow with your business. Consistently deliver industrial quality 3D printed parts.

The Next Generation of

Industrial 3D Printing

LFS or Low Force Stereolithography is the new Form 3 technology. Completely re-engineered 3D printing, that dramatically improves the print process by reducing forces on the part.

| Units | Metrics | US |

|---|---|---|

25μmXY Resolution |

0.001inXY Resolution |

|

250mWLaser Power |

250mWLaser Power |

|

25 – 300μmLayer Thickness |

0.001 – 0.012inLayer Thickness |

|

4.5 × 14.5 × 18.5cmBuild Volume |

5.7 × 5.7 × 7.3inBuild Volume |

40,000,000 Parts Printed With Formlabs Technology

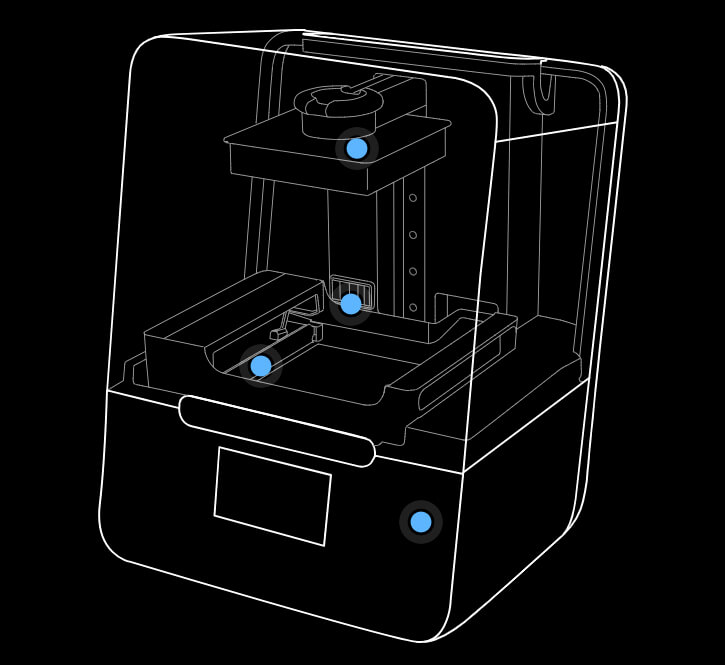

Low Force Stereolithography (LFS)™ uses a flexible tank and linear illumination to deliver groundbreaking print quality and printer reliability.

Pinpoint Precision

A Specially designed Light Processing Unit utilises a system of compact mirrors and lenses to deliver an extremely accurate and repeatable print.

25μm

XY Resolution

250mW

Laser Power

Crisp, clean features:

The Form 3 guarantees a clean and defined laser spot by passing through a spatial filter.

Consistent printing:

To ensure a uniform print quality across the entire print surface, the Form 3 uses a parabolic mirror. This ensures the laser is perpendicular to the build platform.

Faster than ever:

Obtaining precise control and high speed through the use of a high frequency galvanometer.

Closed-loop calibration:

Internal optical sensors constantly correct for power and scale.

Simple materials management:

Utilising the current Formlabs material cartridge system.

User-replaceable components:

The new design in Form 3 uses component modules, meaning many replacements can be done in-house. Things like the Light Processing Unit, rollers and optic window.

Nonstop Printing

Bring your creative ideas to reality with Form 3. Integrated sensors maintain the correct print conditions and alert you by email on the status of your prints.

Grows With Your Business

Scale your printing capacity as your business needs it. Move through prototyping to production and expand into new areas knowing production is scalable.

Industrial quality for all:

Get industrial capabilities at a fraction of the cost of industrial units.

Get started now:

The Form 3 printer come ready to print, there is no complex setup process.

Avoid delays:

Form 3 brings your production in-house. Enjoy fast turnaround time and the flexibility you need to get to market faster.

White Paper

Introduction to SLA

Learn how stereolithography 3D printing can benefit your work.

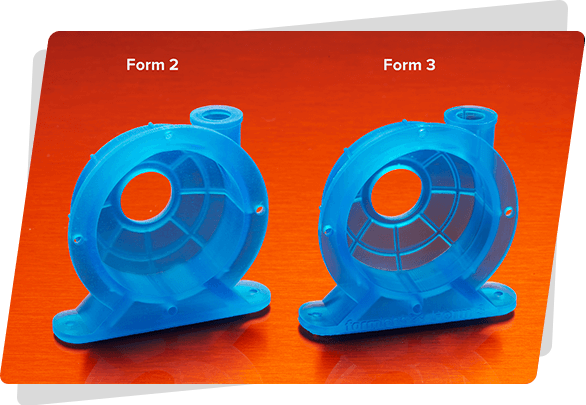

Form 2 vs Form 3 Prints

What’s New and Improved

How does the Form 3 re-engineered Low Force Stereolithography printing process improve the print quality? Find out how the LFS process works and how it improves the finish on the parts.

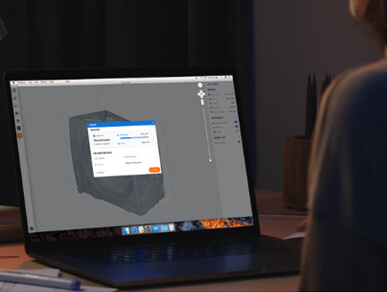

Design

Design your model in standard CAD software and import an STL or OBJ file into our PreForm print preparation software.

Send prints over WiFi, reprint previous jobs, and manage your print queue with ease with the printer’s intuitive touchscreen interface.

Post-Process

Easily tear away fine-touch supports after printing, then transfer parts to Form Wash and Form Cure for simplified rinsing and post-curing.

One Platform, 20+ Materials

There is a resin material for almost every situation. If you have an existing Form 2 system, you can share your resin canisters between the Form 2 and Form 3 systems.

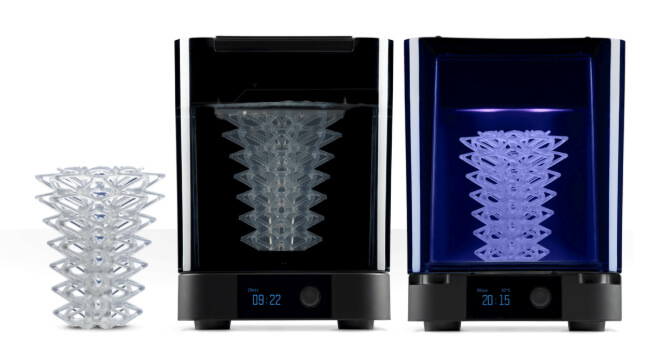

The Perfect Finish

Form Wash and Form Cure streamline and automate rinsing and post-curing of prints. Consistently produce high-quality results with less time and effort.

Built for Teams

Plan and manage your print queue in PreForm and manage printers and teams through your online Dashboard.

Support When You Need It

Get helpful, human service when you need it from a Formlabs expert, with plans that scale with your business.

How does Formlabs fit into your workflow

Contact a Formlabs 3D printing specialist for a free consultation.

Contact Sales

Start today

Start scaling your prototyping and production today.

Form 3 is available for order today. Be one of the first to get your Form 3.

Form 3L available for pre-order now.

Order the Form 3 Complete Pack